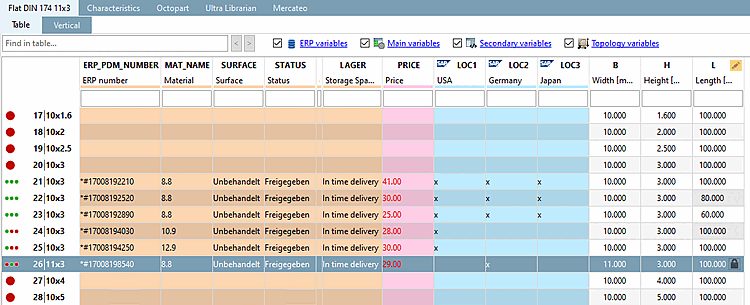

The following figure shows a part with value ranges (semi-manufactured products) in the PARTdataManager. Different lengths receive their own ERP number. Aside from that, different materials were used and a "real" geometric variant for the variable "B" was set.[10], [11]

The following figure shows how the variants are displayed in the PARTlinkManager.

All rows are based on the same row ID [Line ID] and differ in the row subID [Line sub ID]. "Real" variants (change in a NON-value range field) have the entry 1 in the Variant column.

The table describes the differences in detail:

[10] Whether a separate number should be used for different lengths is defined administratively under PARTadmin -> Category -> Configuration files -> $CADENAS_SETUP -> plinkcommon.cfg -> Block PARTdataManager -> key LockDimRange=0/1. In the example, LockDimRange=1 is set.

Detailed information on this can be found under Section 4.16.2, “ Pin dimension feature on/off / plinkcommon.cfg -> Block [PARTdataManager] -> Key "LockDimRange" ” in PARTsolutions Administration - Manual .

[11] An example for importing variants with PARTdataCenter can be found under Section 1.1.5, “ Dimension search - Automatic assignment based on standard information such as standard number, dimension, material, etc. ” in PARTwarehouse Manual